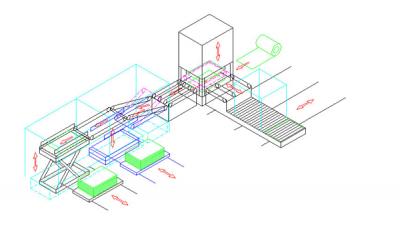

Blanking Line

KIA MOTORS, Korea

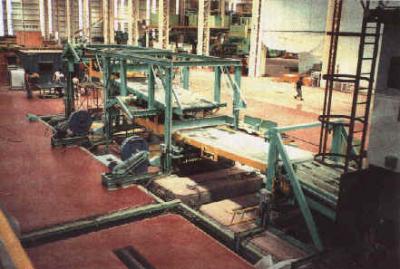

This blanking line handles and stacks thin sheets for car body skins. The stacks weighing up to 6T are collated and tamped onto heavy powered trolleys. These two trolleys are carried on rails mounted on scissor lifts which when full are lowered to floor level and powered out to be unloaded onto AGV’s for pressing elsewhere. Steel sheets up to 4000mm x 2000mm are fed from the press at up to 130m/min. Some are rectangular and others trapezoidal. They must not be scratched. The magnetic telescopic conveyor takes the blanks quickly onto the diverter and then to one of the two pilers. These photographs in our works show generally show various modules of this large system as shown below.

Diverter

Video 1 - Twin Stackers

The diverter receives the blanks and can either feed to the lower piler position or the upper one. This enables continuous production.

There is a further provision for the diverter to be lifted so that off-cuts can be loaded onto a scrap conveyor during set up.

Side tamping guides which are turnbuckle shaft driven, nestle either side of the stacks as they are formed. End tampers fold up clear of the stack during removal.

Front Piler

At the face of the press is the front pier which consists of a rail mounted, telescopic, elevating feed-out conveyor. It will move out of the way during press tool change over.

Video 2 - Front Piler for eccentric shaped sheets