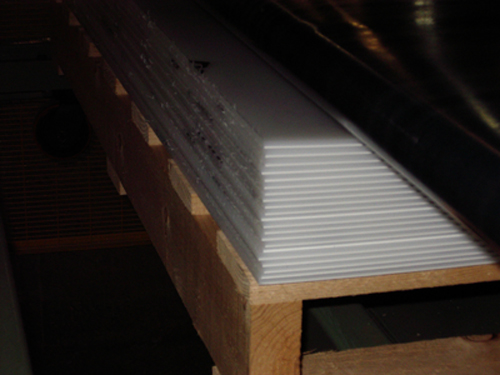

Extruded plastic sheet

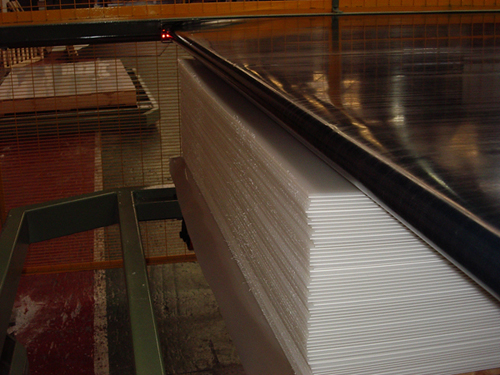

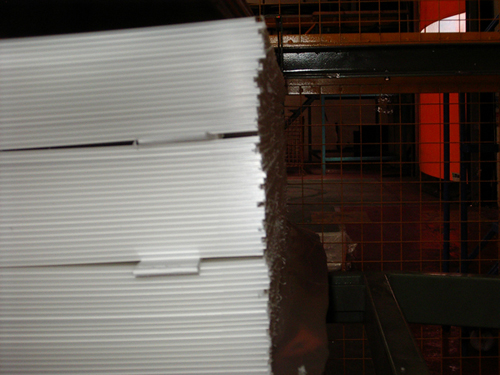

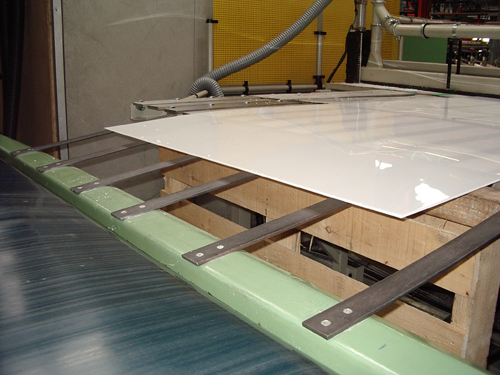

This system is designed to receive an extruded sheet on the in-feed end of a fixed bed and transport it to a position where it will be deposited in a pre-determined position. Repetition of this cycle results in a stack of sheets being formed, with the option of multi-stacking to be employed for smaller sheets. Sheets are sheared to length prior to being fed into the stacking system.

This system was designed to handle from 600mm to 4500mm long and up to 3 seperate stacks longditudinally. The normal pack weight is 1T.

The belt stacker is designed as an extending belt conveyor, comprising a large stationary skid bed frame and an extending skid bed. Multi-stacking is achieved by means of an infinitely variable lay down position, defined by a rotary encoder signal through the central system. The ‘Load build assembly’ comprises a Scissor Lift, Load Trolley and Transportation Pallet.

Operators input data into the HMI screen to determine sheet length and stack configuration, etc. This whole assembly is mounted on wheels and rails to enable the system to be ‘rolled out’ for up-line maintenance or re-setting.

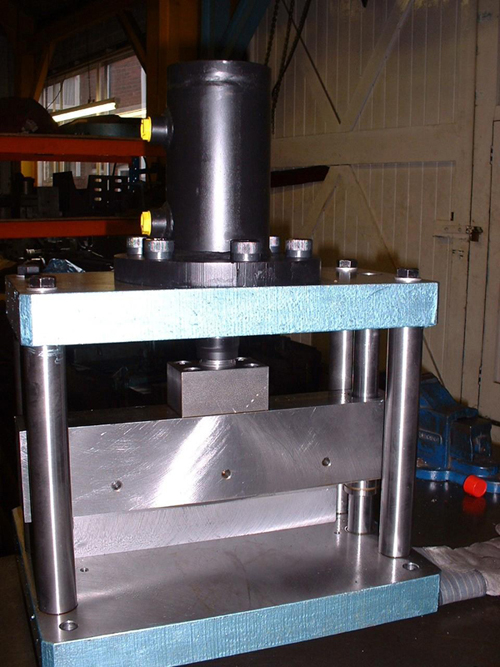

Before the sheet is sheared to length side trim is removed and cut up by 2 hydraulic fast-acting cutters for material return for regranulation by a conveyor system.

www.thevitagroup.com

Video 1 - Extruded sheet stacking

Video 2 - Demo of single and 3 stack laydown