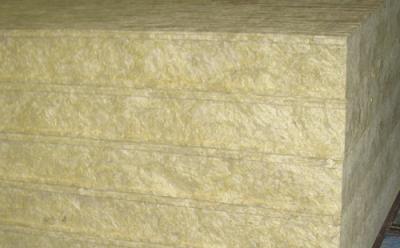

Rockwool

The system receives palletised wall insulation stacks at one end and deposits de-palletised, split stacks at the other end of a 5 meter slat band conveyor. The object of the project was to enable transport to bring in higher stacks of material than the P & P was capable of using.

A de-stack unit separates the stack from the pallet.

The automatic pallet re-stacking unit stores multiple pallets ejected from the main slat band conveyor. The pallets are ready for unloading by fork lift truck.

The insulation stack (less pallet) is lowered directly onto the slat band conveyor, whereby it is transported to the stack splitting station.The de-stack unit engages both sides of the stack and the top half of the stack is lifted from the bottom half which is then free to be transported to the end of the slat band conveyor. The top half is now lowered onto the slat band conveyor also.

www.rockwool.co.uk

Video 1 - De-Stacking System

Video 2 - Rockwool Pick and Place